-

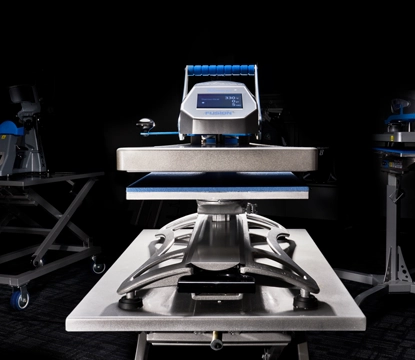

Made in America. Built for Business. Tariff-Free.

Start smart and stay ahead—with no tariff hikes or import delays. Hotronix® heat presses are proudly made in the USA, in stock, and ready to ship.

Explore Hotronix® Presses -

Turn Your Heat Press Into Profit.

Your success is our investment. Buy a new Hotronix® heat press and we'll give you $1,000 in FREE transfers. Take advantage of this limited time offer today!

Learn More -

Start Smarter. Stock Up. Save Big.

Add $500 in ANY HTV to your cart and get a Romeo® Cutter for only $199. Take advantage of this limited time offer while supplies last!

Unlock Now

*Ends 12/19/25. -

The HTV That Makes Customization Easy

Siser® EasyWeed® is the go-to heat transfer vinyl for fast and durable designs— now available at STAHLS.

Explore EasyWeed®

Discover why creators everywhere choose EasyWeed® as their HTV solution. -

Turn Up the Heat on Holiday Sales

Get inspired to create custom holiday gifts that shine. The STAHLS’ Holiday Heat Printers Lookbook is your recipe book for festive success, packed with creative projects, trending finishes, and expert tips to help you press, personalize, and profit all season long.

Download Now -

The Future of Emblems is Here

LIQUID 3D™ sets a new decoration standard with premium, dimensional finishes fulfilled and shipped in 5 days or less.

Learn More about Liquid 3D

No minimums. Fastest Turnaround. Only from STAHLS’ Fulfill Engine™. -

Fresh Looks for Fall Fans!

See what’s hot for the upcoming fall season. Explore the latest blank styles and top decoration trends driving fall fanwear in 2025.

Download the FREE Guide -

Made in America. Built for Business. Tariff-Free.

Start smart and stay ahead—with no tariff hikes or import delays. Hotronix® heat presses are proudly made in the USA, in stock, and ready to ship.

Explore Hotronix® Presses -

Turn Your Heat Press Into Profit.

Your success is our investment. Buy a new Hotronix® heat press and we'll give you $1,000 in FREE transfers. Take advantage of this limited time offer today!

Learn More

We’re here to provide the education, support, and products you need to grow your custom apparel business

—from heat transfer vinyl and equipment, to DTF transfers and more.

Featured Products

Educational Videos

Resources

Trending Products

Check Out Our Blog Highlights

Customer Inspiration Station

Heat Print Technology opens opportunities and provides solutions not available with other decorating methods. Find inspiration in this gallery of heat transfer designs submitted by STAHLS’ customers. You’ll find the latest sports uniforms, trends, new materials and finishes, plus creative placements only possible with heat printing.

Be more creative, get more inspired; all you need is a heat press.